The Tie-Dye Blue Atoms Model 000 took months to create from its inception at Atoms co-founder Sidra Qasim's desk at the Brooklyn Navy Yard, to the production run at our factory in Busan, South Korea. Since the sneaker was made with an upper of 100% recycled polyester, a first for Atoms, we were able to turn to innovation, using a special sublimation technique with environmentally-friendly ink to print the Tie-Dye Blue effect on to the sneakers because the recycled polyester can withstand the heat. It uses less water than traditional printing. The eyelets are made from recycled brass, and of course, like the original Model 000, it features shoe laces that only need to be tied once, a copper-thread-lined insole, support that moves with you, and an upper that shapes to your foot. Here's a behind the scenes look at the production of the Tie-Dye Blue sneaker at our factory in South Korea:

Made from 100% recycled polyester, the Tie-Dye Blue Atoms Model 000 uses a special sublimation technique with environmentally friendly ink to create the tie-dye print.

The Tie-Dye Blue Model 000 Atoms travel down the conveyer belt at the factory in Busan, South Korea.

A factory worker checks the Tie-Dye Blue sneakers.

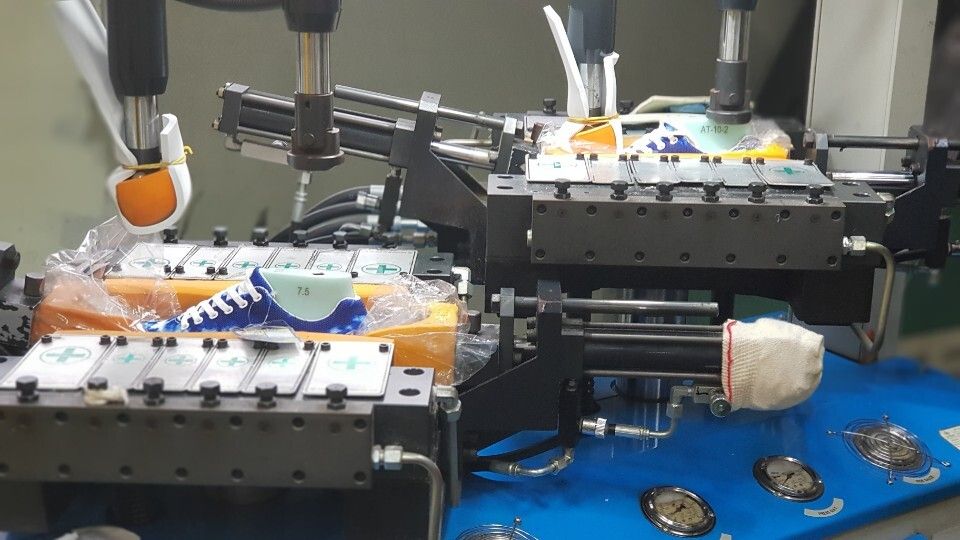

The Tie-Dye Blue Atoms in production.

A factory worker attaches the Tie-Dye Blue Atoms upper to the midsole.

A factory worker checks for quality.

A finished pair of Tie-Dye Blue Model 000 Atoms.

A row of assembled Tie-Dye Blue Atoms.